Innovation must press forward even during challenging times. Four months ago, I never would have imagined being confined to my home office prototyping from 3D-printed parts. Fortunately, I’ve had some practice. My home shop/office is well-equipped with two 3D printers, a butcher-block work surface for cutting and sculpting, an electronics prototyping area, and a computer desk where I do most of my Computer Aided Design (CAD) modeling and analysis. I’ve used my shop to design several customer prototypes ranging from scaled looks-like models to fully-functioning mechatronic test samples. In many ways, it looks like our DISHER studio. It’s just smaller and comes with the lovely addition of my wife in the office across the hall.

When helping customers with new product development, the projects we work on move quickly and need a high rate of innovation. We have no time to wait for a pandemic or the competition to pass us by. Innovation must continue to forge forward, and prototyping is key to answering several questions in order for progress to be made. Designing parts and prototypes for customers with limited supplies and resources takes creativity and ingenuity—and I love every minute of it!

WHY USE FAIL-FAST-FORWARD PROTOTYPING?

Prototyping is a great way to quickly learn, make mistakes, and try again. Maybe it’s the first couple of pancakes that you had to throw out after attempting family breakfast or the crumpled piece of paper when trying to write a story (or a blog). Think back to your high school science class when you had to come up with a hypotheses that would solve your problem statement. How many times was your hypothesis correct on your first try?

We are constantly crafting our own hypotheses for product development and beyond with a fail-fast attitude. While working from home, it might be ideating in a virtual Whiteboard Workshop, developing CAD models remotely that we run through structural analysis, or building up or sculpting foam in a make-shift home office/shop. We help our customers through their unique development journey by creating the right prototype at the right time so we can answer the right questions to move forward.

One of the biggest hurdles of prototyping from home is not being able to review the prototypes in person with the customer. Quick, direct feedback is important because many prototypes are used to communicate how something might look or work. To solve for this, I cobbled up some rigging to create a camera arm that allows me to provide close-up views of prototypes. This enables the team to experience a virtual design review and gives our customers the opportunity to provide valuable feedback before making a delivery.

WHO ARE WE PROTOTYPING FOR?

While it takes a lot of skill to be able to create different types of prototypes, it’s important to understand the need for each one before heading to the shop. At DISHER, we like to have a good idea of the people who will be influenced by the product before designing it. Human-centered design is important to us whether it is the end user, an installer, a retailer, or the person on the manufacturing assembling line. We seek to understand their expectations so that our prototypes will reflect their needs and we can test to those needs. Some prototypes are built to learn about ergonomics while others are meant to communicate an experience or a feature. This is what makes prototyping so important. Prototyping breaks problems down into smaller parts that can be solved more quickly and be developed more economically.

Though design processes vary from company to company, they are usually made up of cycles of design-prototype-test that are then iterated on until there is confidence in the design. The prototypes will often change overtime from simple to complex, meaning the level of accuracy to a final design changes as the product is further tested. We call this the fidelity of the prototype. A low-fidelity prototype might be a cardboard mockup or even a napkin sketch with no usable features. Whereas a high-fidelity prototype might be 3D printed and painted to become a looks-like and works-like final product.

Quick thoughts: Regardless of the fidelity of a prototype, the goal is always the same—to learn as much as we can, as quickly as we can. Whether it is used to test the physical strength of the product or get feedback from users, a prototype will allow the team to minimize risk while moving the design forward through learning and iterating.

WHAT DOES A GOOD PROTOTYPE LOOK LIKE?

Prototypes are unique to the problems being solved. First-phase prototypes are often brain-child sketches from a wide variety of engineers, designers, and manufacturing gurus (yeah, we invite everyone) during one of our ideation workshops. It’s not uncommon for us to have over 100 sketches and concepts after a Whiteboard Workshop that we can vet and iterate upon.

Once the top concepts are narrowed down, they are passed on to an Industrial Designer who will think about how a user might see and interact with the product. Often the designer will create a stylized sketch or rendering to help the team understand what the product might look like while being used. This helps uncover any blind spots the team might have had and creates a better user experience as the design is further developed.

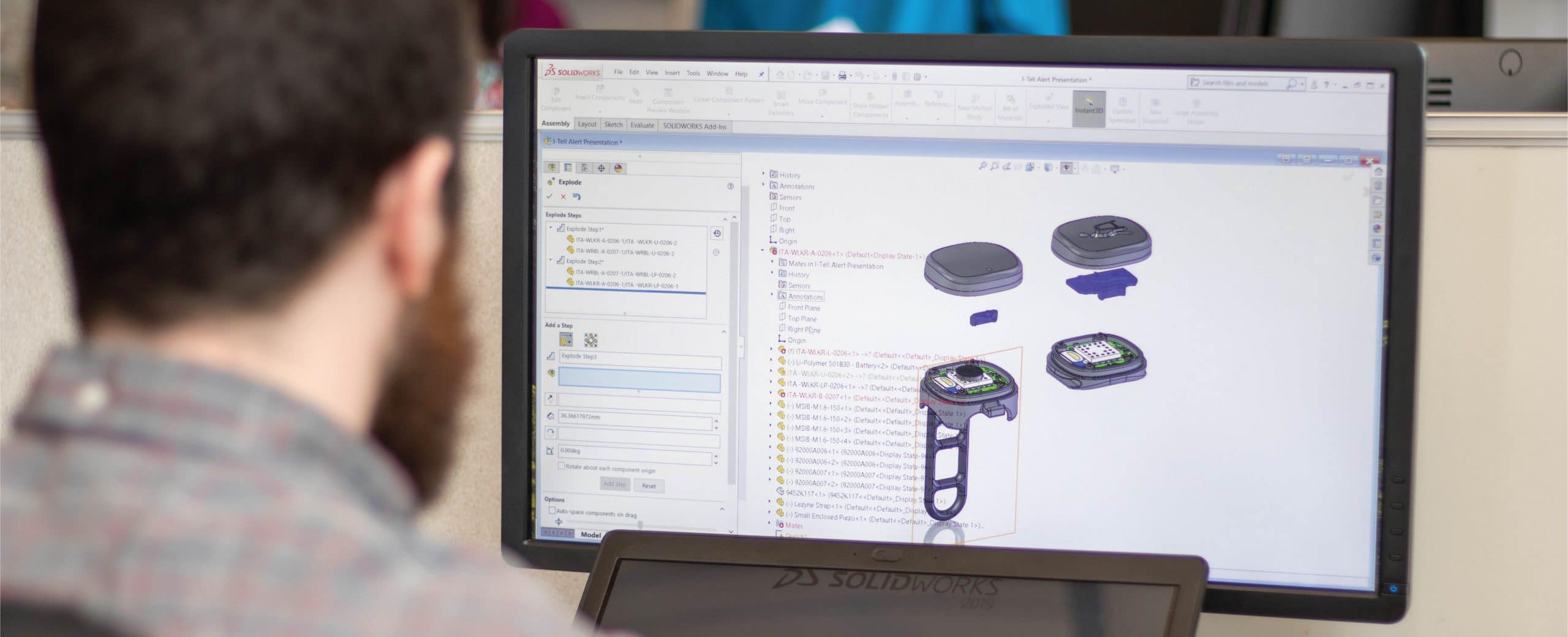

After the team talks through different styling options from the Industrial Designer and gathers more user feedback, the designer or an engineer will start developing models using CAD. These models allow the team to scrutinize the geometry and even some of the manufacturability of the product. Using these computer models, we can then use rapid prototyping tools such as 3D printing or CNC milling to create physical prototypes for testing.

It’s always helpful to identify what things you want to learn before making a prototype. This can prevent you from spending too much time or money on something that might be answered with a simpler representation. A good example of this is performing 3D stability tests in CAD software early on before you have physical prototypes. Because CAD programs can quite accurately measure the physical properties of an object, it’s possible to do stability tests and make changes in CAD before parts ever enter a prototype shop. This saves time and money with very low risk.

Quick thoughts: Do you think coming up with 100 ideas and concepts is impossible? We consider quantity over quality during the first stages of ideation. Come up with as many quirky, crazy ideas as possible. Try not to use “But…” or “No…” during ideation and instead consider “How might we…” and hold any questions or qualms until the ideas have been vetted through User Desirability, Commercial Viability, Production Feasibility.

Related Article: Effective Prototype Development

PROTOTYPING CAN HAPPEN ANYWHERE.

The importance of prototyping within the product design process hasn’t changed, whether it happens in our home or at the office. As we all phase back into our office spaces, I am hopeful that many of the advancements we’ve made in remote-home workplaces will continue to evolve as we help our customers move forward with speed for a sustainable future. During times of change and transition, we have a great opportunity to innovate and ultimately Make a Positive Difference in the lives of others.

Written By:

Dan Parker

Concept Engineer

DISHER Newsletter

Sign up to receive articles and insights, delivered monthly.

Schedule a no-committment project call

Reach out to discuss your project to find out if DISHER could be a good fit for you.